In order to scientific verification and valid comparison of thermal insulation property, we select a famous brand down jacket as the comparing object.

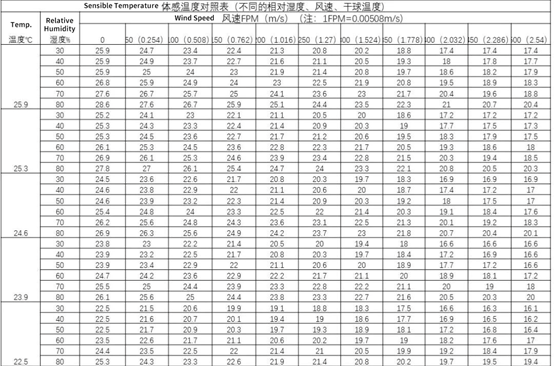

The relationship between wind speed, relative humidity and thermal insulation

When wind speed increases by 1 m/s, sensible temperature drops by 2-3 centigrade, so setting wind force as 3 grade for clothing thermal insulation property test is relatively scientific.

Precision of instrument determines value of experiment

Thermodetector

Famous FIuke-F52-2 thermodetector,To avoid errors generated by probe touching human body, we only measure temperature of the air in between outer garment and inside clothing。

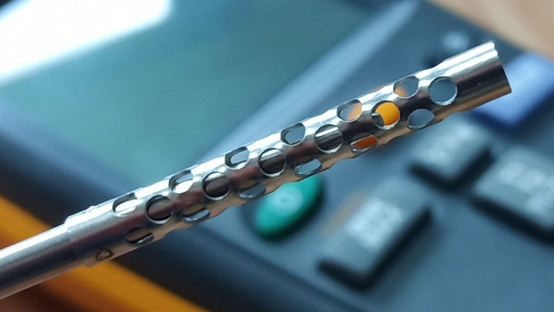

Air inductive probe

By using professional air inductive probe, we don’t need worry about data variation caused by position of the probe either nearby outer garment or inside clothing. The verification is very scientific.

Anemometer

Testo 416-professional anemometer can accurately measure ambient wind speed, so we don’t need worry about measurement errors.

Ambient temperature/relative humidity meter and timer

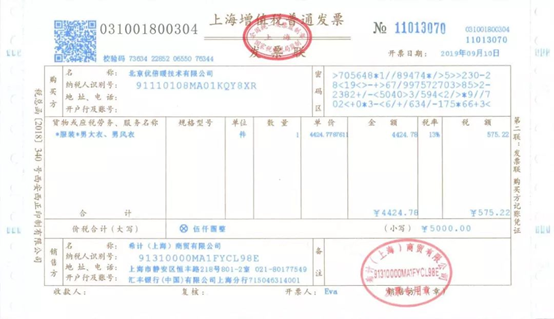

Time and place

12:00 PM, 11th Sep. 2019, a refrigeration warehouse in Beijing,

Tester

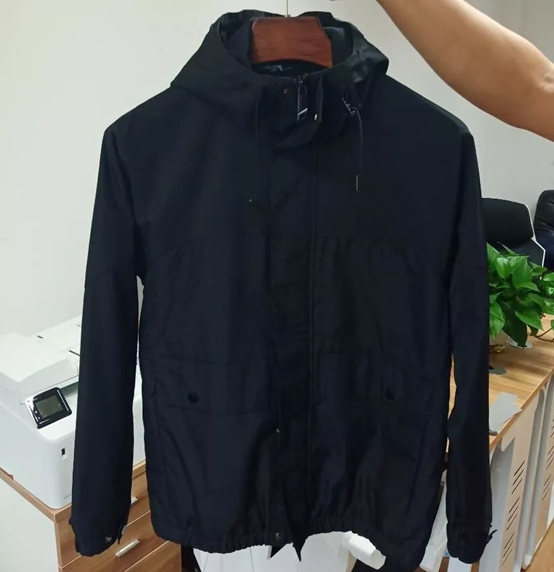

Testing garment

Y-warm business wind coat

Total thickness of Y-warm business wind coat is around 5 mm. Outer fabric thickness is 0.32 mm, lining thickness is 0.1 mm, and two layers Y-warm with 1.4 mm total thickness is filled in between fabric and lining.

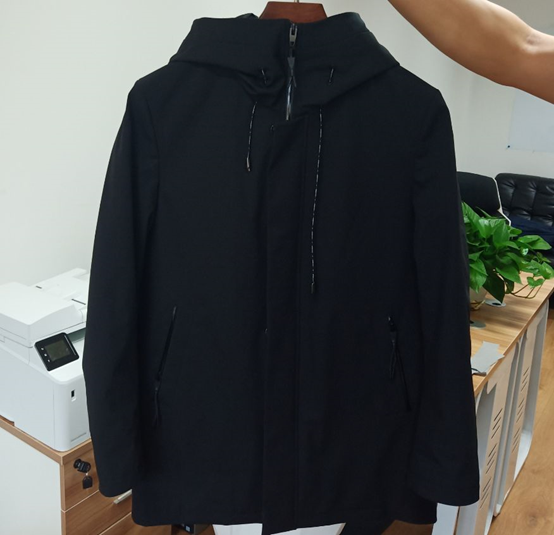

Famous brand down jacket

Famous brand down jacketTotal thickness 25 mm,Article number: 5501MB, size: XL, down weight: 118 g (down content 90%)

Y-warm jacket

Total thickness of Y-warm jacket is around 4 mm,

Outer fabric thickness is 0.165 mm, lining thickness is 0.2 mm, and two layers Y-warm with 1.4 mm total thickness is filled in between fabric and lining.

Tester’s dressing ways

Garment test sequence

Considering physical exertion affects body temperature over time, we placed Canada Goose down jacket as second in test sequence.

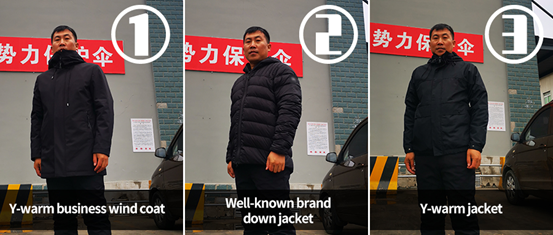

Test place preparation

Plane graph

Temperature of refrigeration warehouse

Setting temperature: -20 centigrade, Actual temperature: from -10 to -12 centigrade.

Wind speed setting

When wind speed increases by 1 m/s, sensible temperature drops by 2-3 centigrade. The distance between tester and fan is 1.5 m, wind speed is 3.5-4.5 m/min, equals 3 grade breeze.

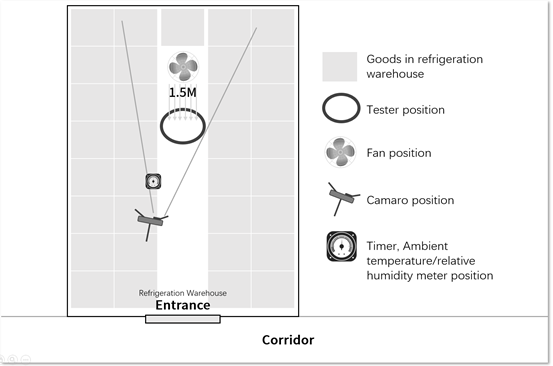

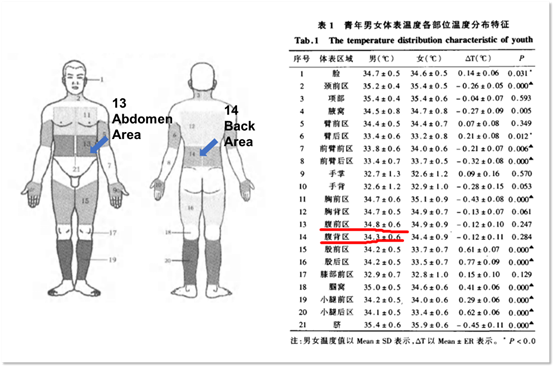

Body temperature distribution

To avoid excessive temperature errors, we choose the part with moderate body surface temperature for measurement.

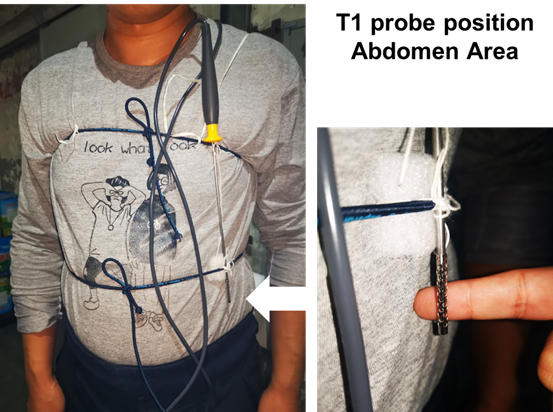

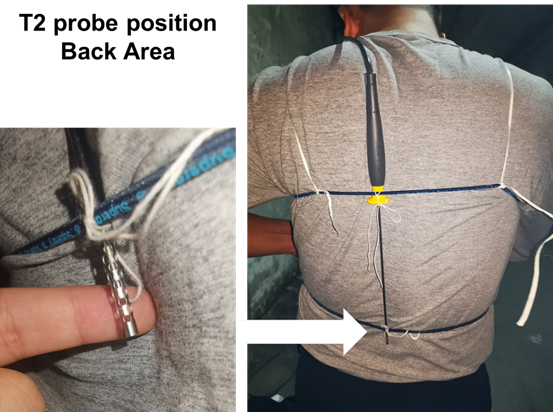

Two testing points

Two probes are placed respectively at abdomen and back area, and connected to the same equipment. Probes' position are fixed during test, and kept 1cm apart from tester's body, making the test result more scientific and effective.

Probes are fixed tightly, in three tests they are placed at the same position

Test method

Step 1: The tester stops movement in air-conditioned room outside of refrigeration warehouse for 10 minutes, if probe shows temperature is stable, record initial temperature and start the test;

Step 2: Enter refrigeration warehouse, start timing, and record the whole test process and temperature change through video;

Step3: Set fan speed, and keep distance between tester and fan is 1.5 m, let fan blow tester backside, total test period is 20 mins;

Step 4: After each garment testing the tester need take a 30 mins break in air-conditioned room, start another testing until he fully recovers strength and body temperature.

Start test

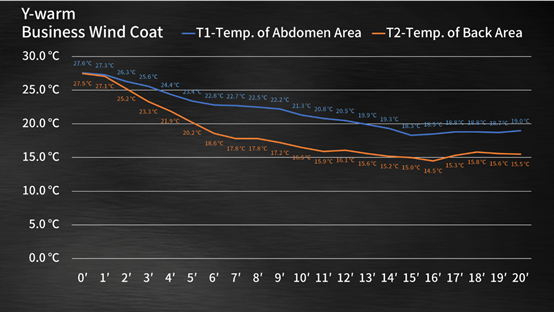

Test of Y-warm business wind coat

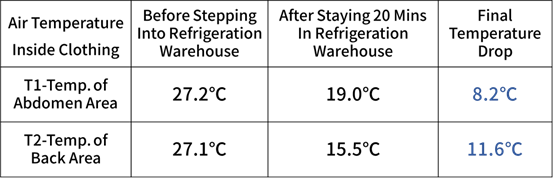

Before stepping into refrigeration warehouse, air temperature inside clothing as follows

(Abdomen area: 27.2℃)(Back area: 27.1℃)

After staying in refrigeration warehouse for 20 mins, air temperature inside clothing as follows, Abdomen area: 19.0℃, Back area: 15.5℃

Temperature decline curve in 20 mins test

Data comparison of 20 mins test

Test of Canada Goose down jacket

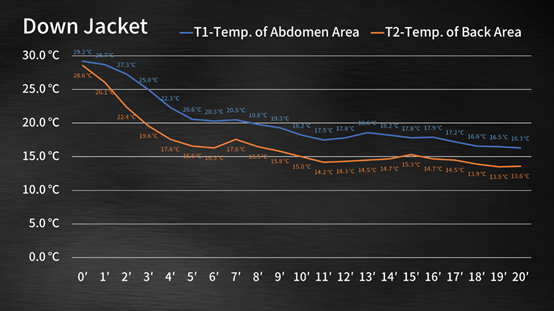

Windbreak at bottom of down jacket must be tightened, otherwise cold air can penetrate into and makes temperature drop quickly

Before stepping into refrigeration warehouse, air temperature inside clothing as follows

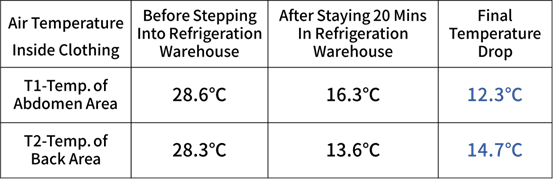

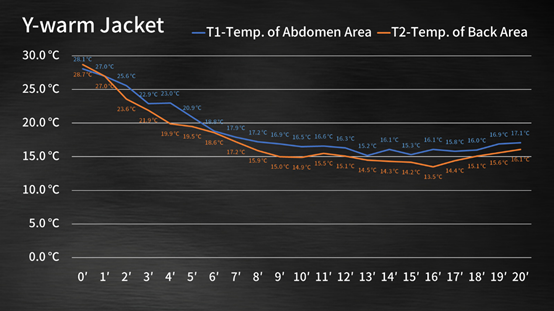

(Abdomen area: 28.6℃)(Back area: 28.3℃)

After staying in refrigeration warehouse for 20 mins, air temperature inside clothing as follows, Abdomen area: 16.3℃, Back area: 13.6℃

Temperature decline curve in 20 mins test

Data comparison of 20 mins test

Test of Y-warm jacket

Before stepping into refrigeration warehouse, air temperature inside clothing as follows

(Abdomen area: 28.0℃)(Back area: 28.8℃)

After staying in refrigeration warehouse for 20 mins, air temperature inside clothing as follows, Abdomen area: 17.1℃, Back area: 16.1℃

Temperature decline curve in 20 mins test

Data comparison of 20 mins test

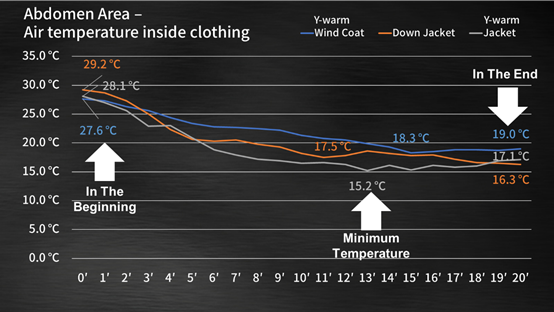

Test result comparison

Abdomen area- Air temperature inside clothing

Without blowing in front side, temperature change range and speed of the three garments are roughly same.

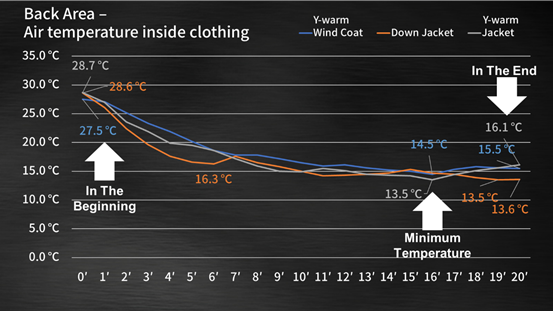

Back area- Air temperature inside clothing

In breeze condition, temperature change range and speed of down jacket is even greater.

According to this test we get the conclusion: A cold proof clothing made by filling 1.4 mm total thickness 2 layers Y-warm in between fabric and lining, in 3 grade wind speed, has a little bit better thermal insulation property than 25 mm thickness Canada Goose down jacket.

Result analysis

Wind speed has a great influence on thermal insulation of clothing. Under influence of wind, dividing lines of down jacket become the shortest board of "wooden barrel", affect its overall thermal insulation performance. So in the real world Y-warm has more advantage in thermal insulation application.